Britannia’s water pipes were completely replaced with new PEX pipe connectors, guaranteed up to 100 psi. A Par-Max Plus, six gallon per minute diaphragm pump was also installed, increasing the pressure from 35 psi to 60 psi, thereby giving “household pressure” to every faucet in the boat, including both shower heads.

A water hose connects to a dock faucet and a pressure reducing inlet on the boat. This reduces municipal water pressure, and pressurizes the boats water system. Britannia had this system built in when new and we liked the convenience. The advantages are, constant pressure in the boats water system without using pumps or battery power, a more even flow than a small pulsating pressure pump can deliver for say, a shower, and also silent operation. But if nobody was on board there would be nothing to prevent the boat flooding completely in the event of an internal pipe failure.

A water hose connects to a dock faucet and a pressure reducing inlet on the boat. This reduces municipal water pressure, and pressurizes the boats water system. Britannia had this system built in when new and we liked the convenience. The advantages are, constant pressure in the boats water system without using pumps or battery power, a more even flow than a small pulsating pressure pump can deliver for say, a shower, and also silent operation. But if nobody was on board there would be nothing to prevent the boat flooding completely in the event of an internal pipe failure.

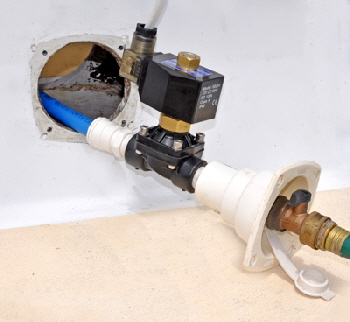

As an added safeguard a shut-off tap was fitted at the hose and pressure connection, just in case anyone switched the dock faucet on. However, this was still not an automatic safety measure, so a shut-off solonoid was fitted on the inwaterl line with a latching relay incorporated in the circuit.

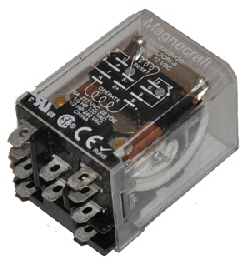

The 12-volt solenoid water shut- off valve is normally open, but instantly closes when voltage is applied. It is fitted directly after the pressure inlet and wired to the bilge pump float switch. When the bilge pump is activated by the float switch it lowers the water and the secondary circuit of the latching relay stays live and keeps the water shut off valve closed even if the float switch deactivates. The relay powers off when the circuit is manually switched off at a breaker. Xoro.com Part # 785XBXCD-12D.

The 12-volt solenoid water shut- off valve is normally open, but instantly closes when voltage is applied. It is fitted directly after the pressure inlet and wired to the bilge pump float switch. When the bilge pump is activated by the float switch it lowers the water and the secondary circuit of the latching relay stays live and keeps the water shut off valve closed even if the float switch deactivates. The relay powers off when the circuit is manually switched off at a breaker. Xoro.com Part # 785XBXCD-12D.

The system now has multiple levels of manual and automatic safety.

and a fail-safe shore water supply system.