A break in the pressurized shore water line caused a major flooding in Britannia that might have sunk her had I not managed to stop it. I subsequently stripped and thoroughly cleaned five electric pumps that worked flawlessly afterwards. After changing the engine oil the engine started as usual so I assumed the starter motor was fine, and I confess I also relied upon the often used, but flawed boating aphorism, "If it ain't broke, don't fix it." During the hot summer months in Florida we hardly visited the boat anyway and rarely started the engine.

Later the starter began to turn slower and slower, as though the dedicated start battery was at the end of its five year life. I installed a new battery but without any change in the sluggish turnover that was now hardly sufficient to fire the engine at all. I checked and cleaned the heavy duty cable connections but it made no difference. There was only one thing to do; remove the starter and examine it.

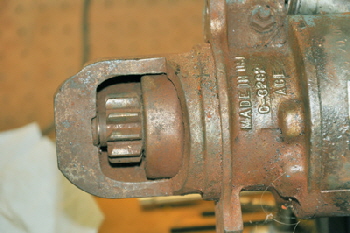

The thing about starter motors on heavy diesel engines is; they're heavy! My engine is a Perkins 4.236 weighing half a ton and the starter is bolted low down in the bowels of the bilge with three very rusty 3/8" inch nuts, one of which is almost impossible to reach with a wrench. After hanging upside down over the engine for half an hour I finally hauled it out using the cable attached to the solenoid. The machine is 15" inches long and weighs 34 lbs. A small boat could use it as a mooring buoy.

|

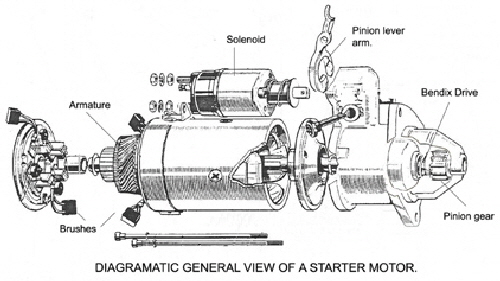

There are two main parts to these normally very reliable starters. There is the solenoid that throws a tiny pinion gear into engagement with the flywheel on the engine. It is called a Bendix drive after the inventor; Vincent Bendix patented it in 1915. The second and much larger part is the actual starter, with its armature that spins the engaged pinion gear and turns the flywheel, starting the engine. There could be many reasons why this was not happening, so everything needed looking at. I started with the solenoid.

There are two main parts to these normally very reliable starters. There is the solenoid that throws a tiny pinion gear into engagement with the flywheel on the engine. It is called a Bendix drive after the inventor; Vincent Bendix patented it in 1915. The second and much larger part is the actual starter, with its armature that spins the engaged pinion gear and turns the flywheel, starting the engine. There could be many reasons why this was not happening, so everything needed looking at. I started with the solenoid.

Solenoid

After securing the starter firmly in the jaws of the big swivel vice in my garage I unscrewed the two bolts securing it to the starter casing, along with the screw holding the electrical cable to the body. The solenoid still would not come away from the body until I discovered it needed rotating a little to dislodge it from the groove it was locked in. It then almost removed itself, due to a large spring inside the solenoid that keeps the pinion disengaged until activated. Removing the solenoid revealed the large 1”� inch diameter piston that throws the pinion gear forward about 3/4" inch to mesh with the flywheel. There is actually nothing else inside the body of the solenoid, all the electrics are in the end cap.

After securing the starter firmly in the jaws of the big swivel vice in my garage I unscrewed the two bolts securing it to the starter casing, along with the screw holding the electrical cable to the body. The solenoid still would not come away from the body until I discovered it needed rotating a little to dislodge it from the groove it was locked in. It then almost removed itself, due to a large spring inside the solenoid that keeps the pinion disengaged until activated. Removing the solenoid revealed the large 1”� inch diameter piston that throws the pinion gear forward about 3/4" inch to mesh with the flywheel. There is actually nothing else inside the body of the solenoid, all the electrics are in the end cap.

I unscrewed the two small electrical terminals and the screws holding the end cap of the solenoid, and carefully removed the cover. The brass contacts were very badly pitted, telling me that a good contact was no longer being made. I cleaned everything until the contacts gleamed then I scrubbed the inside of the end cap. I greased the piston and oiled the lever arm and pinion shaft with waterproof lithium grease.

When the starter is activated an electro/magnetic field is created in the solenoid, causing the piston to retract against the spring and throw the pinion gear with great force into mesh with the flywheel. At the end of its travel the piston also pushes the contacts together, transmitting the full voltage from the battery into the starter.

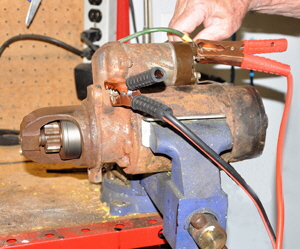

After replacing the solenoid on the motor, it can be tested by applying a 12-volt current to the small terminal, and an earth, whereupon the pinion gear should shoot forward on the shaft. Warning. Do not connect the heavy duty battery wire to the solenoid during this test, or the starter will also activate and might easily jump out of the vice.

STARTER BODY

I next withdrew the two long screws from the rear of the starter casing and removed the backing plate. This revealed an unbelievable mass of sludge and grime covering the four brushes and the commutator. Some of it was so heavily encased it refused to be dislodged even after prodding with a screwdriver, while other parts dropped out in chunks of dry earth. It was unlikely that it came in during the flooding because that was fresh water from the dock faucet, but it was quite remarkable that the starter had worked at all.  The hardened muck took some removal. I first sprayed the inside with degreasing liquid then washed it out with a strong jet of water from a hose, three times, then dried it out with a heat gun.

The hardened muck took some removal. I first sprayed the inside with degreasing liquid then washed it out with a strong jet of water from a hose, three times, then dried it out with a heat gun.

I decided to remove the armature from inside the outer casing to inspect the windings. This was done by holding the casing in the vice and pulling the armature out.

The brushes remained attached to the outer casing and the commutator slid off them. The windings inside seemed quite clean, no doubt due to the dousing it had just received. I mounted the armature in the vice with soft jaws fitted, then rotated a strip of 400 grit sandpaper around the commutator until the brass gleamed. The armature windings were then cleaned and the end bearing and throw lever greased.

Before I could reinstall the armature I first had to hold the four brushes apart in the body, so the commutator would slide between them. This was very easy to do with two small slivers of wood wedged between the pair of arms on the brushes. When the armature was fully installed, I just pulled the bits of wood out and the brushes seated perfectly on the commutator. Then I replaced the end cap and screws.

Before I could reinstall the armature I first had to hold the four brushes apart in the body, so the commutator would slide between them. This was very easy to do with two small slivers of wood wedged between the pair of arms on the brushes. When the armature was fully installed, I just pulled the bits of wood out and the brushes seated perfectly on the commutator. Then I replaced the end cap and screws.

My big vice held the starter securely, so I decided to make a bench test of the whole operation. Using a car battery I clipped jumper cables to the larger positive solenoid terminal and the negative to the starter body. Nothing happened until I held a second, thinner wire to the terminal that normally carries the starter wire. The pinion gear flew forward and the motor instantly began spinning furiously. On removing the green wire the motor died and the Bendix Drive retracted the pinion gear

My big vice held the starter securely, so I decided to make a bench test of the whole operation. Using a car battery I clipped jumper cables to the larger positive solenoid terminal and the negative to the starter body. Nothing happened until I held a second, thinner wire to the terminal that normally carries the starter wire. The pinion gear flew forward and the motor instantly began spinning furiously. On removing the green wire the motor died and the Bendix Drive retracted the pinion gear

A final touch was to repaint the whole assembly black, and I had an (almost) new starter motor. It has now performed perfectly on multiple starts even when the battery was low, and it is a reassuring feeling to know the engine will start at the push of the button.