All lines return to the cockpit so noone has to venture on deck in inclement weather or rough seas.

All lines return to the cockpit so noone has to venture on deck in inclement weather or rough seas.

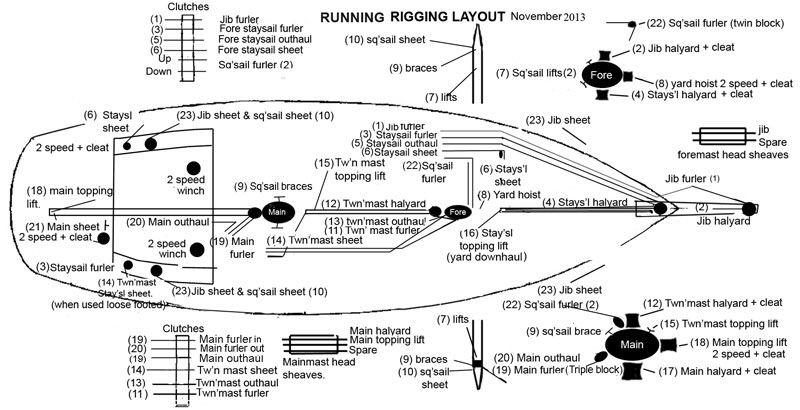

Roller furling makes sail handling easier, every time there is need to reef or furl a sail. However, these systems need more control lines and with five roller furling sails these ropes can become a bit cluttered. Britannia’s cockpit has a wide empty area on either side of the companionway that we call the “rope decks. The main components of this are:

The control lines, sheets, furling lines, lifts and braces for the squaresail.

Two banks of six rope clutches.

Two self tailing winches.

Two rows of five belaying pins.

The controlling lines are modern double braid polyester, 3/8”, 1/2” and 5/8” inch diameters, depending on their job. These ropes are exceptionally strong with very little stretch and also nice on the hands. All these individual lines are shown on the sketch and consist of:

(a) four furling lines that wrap the sails up round their stays,

(b) three out-hauls that unroll the sails,

(c) three sheets that control the booms,

(d) two square-sail furling lines that roll the square-sail up and down.

In addition there are five other control lines, (sheets), that are bent on the clews of the sails and lead into the cockpit through running blocks and fairleads to their own winches mounted on the cockpit comings. Britannia has up-and-over blocks in singles, doubles and triple combinations.

Twelve rope clutches allow ropes to slide through them but lock the rope when the lever is operated. They permit multiple lines to be used on a single winch. To make winch operation a lot easier a powerful electric winch winding machine the Ewincher2 takes all the effort out of winding the winches.

Belaying pins keep the lines tidy on the rope decks and are easy to reach.