The therapeutic benefits of a hot soak have been known ever since man first discovered hot springs, and if you suffer aches and pains after physical work there is nothing finer than to immerse into a nice hot bath, and if this happens to also have invigorating massaging jets, so much the better.

Britannia’s tub has ten adjustable jets directed on back, legs and sides and a slope. There is a nice glass picture of a square rigger with a light behind it and new faucets and a shower.

Britannia’s tub has ten adjustable jets directed on back, legs and sides and a slope. There is a nice glass picture of a square rigger with a light behind it and new faucets and a shower.

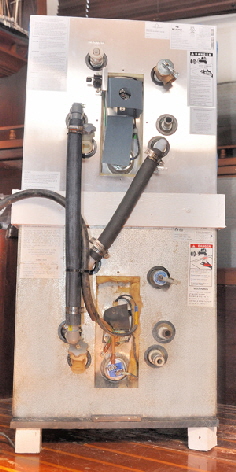

Twin 11 gallon hot heater tanks ensure a continuous flow of very hot engine water pumped through both coils inside the tanks. All hot water pipes are lagged all through the boat.

An adjustable thermocouple temperature controller regulates both emersion heaters through two shore-power receptacles supplying two separate distribution panels. The reason for wiring the two heater elements separately is that if one fails - as they often can after years of use - water can be heated in the other tank from shore-power without running the engine.

The bath pipes and jets had been insulated with foam when it was made so the water temperature does not drop much for a half hour soak.

Raritan electric heads and washbasin make this bathroom reminiscent of some classic Victorian schooner.

|