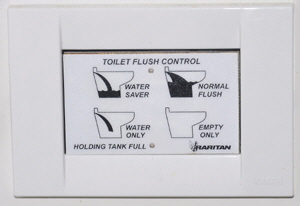

Both Britannia’s heads are Raritan “Elegance” electric models. They performe flawlessly mainly because for about 90% percent of the time they are flushed with clean freshwater.

The corrosiveness of seawater is well known to sailors and even “clear to the bottom” seawater conditions do not prevent calcification of the pipes and valves or its frequent offensive odor. Flushing with freshwater prevents these problems and most manufacturers recommend seawater flush toilets should be flushed with freshwater occasionally. This also prevents that brown ring in the bottom of the bowl.

The corrosiveness of seawater is well known to sailors and even “clear to the bottom” seawater conditions do not prevent calcification of the pipes and valves or its frequent offensive odor. Flushing with freshwater prevents these problems and most manufacturers recommend seawater flush toilets should be flushed with freshwater occasionally. This also prevents that brown ring in the bottom of the bowl.

Britannia’s heads can be easily interchangeable between freshwater and seawater flush.

When in a marina the boat can be connected to the pressurized dock-water supply with a water hose to a pressure reducing regulator in the boat giving constant silent water pressure throughout the boat, including the toilets. There is also an automatic solenoid shut off to this water inlet in case of an internal pipe failure.

When in a marina the boat can be connected to the pressurized dock-water supply with a water hose to a pressure reducing regulator in the boat giving constant silent water pressure throughout the boat, including the toilets. There is also an automatic solenoid shut off to this water inlet in case of an internal pipe failure.

Due to the large fresh water capacity it is possible to leave both heads on freshwater flush, especially on short passages. A urine flush uses about a quarter of a gallon of water i and a full flush about three quarters of a gallon.

Freshwater flushing is a major improvement to a very necessary, but often neglected piece of Britannia’s equipment.