The first time I noticed something was wrong with the water heater on Britannia was when I saw water seepage along the bottom edge of the hot water tank. The tank was in the boat when I bought it twelve years earlier, and it was 30 years old then, so I have no idea how old the actual tank was, perhaps even original equipment from 1977? It was now leaking from somewhere, and leaks from a fresh water tank need to be fixed, asap.

The first time I noticed something was wrong with the water heater on Britannia was when I saw water seepage along the bottom edge of the hot water tank. The tank was in the boat when I bought it twelve years earlier, and it was 30 years old then, so I have no idea how old the actual tank was, perhaps even original equipment from 1977? It was now leaking from somewhere, and leaks from a fresh water tank need to be fixed, asap.

There were no visible signs of a leak from any of the pipe connections on the front of the tanks and there were no other connections. I therefore decided that it must be leaking from inside the tank, which meant dismantling the outer casing to investigate.

All boat water heaters work on more or less the same principal. A tank, usually cylindrical and made of aluminum is encased in an outer box with insulation material in between. Fresh water is pumped into the inner tank from the boats water tanks, where it can be heated by two separate methods. vis:

When 120-volt power is available either from a shore-power connection or the boats generator, an immersion heater element in the tank warms the water exactly like in a house. The Kuuma industries tank is regulated by an electric thermostat to 140F degrees. The second method is to connect the engine water system to the tank that has a coiled pipe inside that warms the water through calorific transfer. The pipe on kuuma tanks is a simple U-shape (not actually a coil), but with the heater pipe inside another. The hot engine water only runs through the inner pipe and the second outer pipe is to prevent dirty engine water from contaminating the fresh water, in the event of a fracture in the inner pipe. The engine pumps its very hot water through the pipe and transfers heat to the fresh water in the tank. This calorific heat exchanging process can produce a higher water temperature over time, then the electric method, because the engine runs at a much higher temperature. In Britannia’s case her Perkins engine runs at 180F degrees, and after prolonged running it can raise the temperature in the tanks to about that temperature.

When 120-volt power is available either from a shore-power connection or the boats generator, an immersion heater element in the tank warms the water exactly like in a house. The Kuuma industries tank is regulated by an electric thermostat to 140F degrees. The second method is to connect the engine water system to the tank that has a coiled pipe inside that warms the water through calorific transfer. The pipe on kuuma tanks is a simple U-shape (not actually a coil), but with the heater pipe inside another. The hot engine water only runs through the inner pipe and the second outer pipe is to prevent dirty engine water from contaminating the fresh water, in the event of a fracture in the inner pipe. The engine pumps its very hot water through the pipe and transfers heat to the fresh water in the tank. This calorific heat exchanging process can produce a higher water temperature over time, then the electric method, because the engine runs at a much higher temperature. In Britannia’s case her Perkins engine runs at 180F degrees, and after prolonged running it can raise the temperature in the tanks to about that temperature.

Both methods can be operated separately or simultaneously, giving great flexibility, for example when the boat is in a marina it is not neighborly to run the engine all the time, but a ready supply of hot water can still be maintained silently from the shore electric supply.

FINDING THE LEAK.

The outer casing of the Kuuma tank is a pop riveted assembly, and I had to drill out 20 small rivets from around the front and underneath the case. Then the complete cylinder was drawn out of the casing with the front panel still attached. The front panel could only be detached from the cylinder after unscrewing the large pressure relief valve and drain tap. These were heavily corroded and needed penetrating oil and hefty wrenches to work them loose. It was immediately obvious from the soaking wet insulation that a leak was occurring somewhere on the cylinder. It is about the same size as a regular propane gas cylinder, but much lighter when empty because it is made of aluminum.

With the tank mounted on a workbench, I connected a garden hose and completely filled the tank, but there was still no sign of leakage either round the body of the tank or the welded connections on the front. I then plugged the outlet and pressurized the tank using the full force of the hose, about 60psi, but still no leaks were visible

With the tank mounted on a workbench, I connected a garden hose and completely filled the tank, but there was still no sign of leakage either round the body of the tank or the welded connections on the front. I then plugged the outlet and pressurized the tank using the full force of the hose, about 60psi, but still no leaks were visible

Next I decided to test the engine pipes inside the cylinder. If a pipe had fractured it might be possible that engine water was leaking into the fresh water side. However, this still did not explain how water could find its way to the outside of the casing, when there was no longer any visible leaks?

I first turned the cylinder upside down to make sure there was no water left in it, then I attached the water hose to the engine inlet pipe, and flushed dirty water out from the outlet. I then sealed the outlet and pressurized the pipe but I didn't have a water pressure gauge, so I left the pressure on for 15 minutes. Then I inverted the cylinder and to my relief not one drop of water came out of the freshwater pipes. This proved that the engine pipe was still sound. So where was the leak, if not in the cylinder?? The mystery thickened.

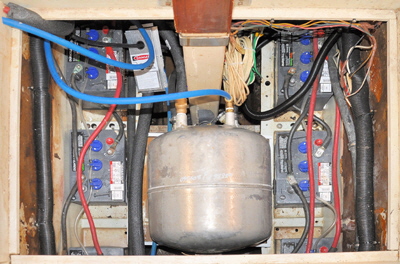

TESTING THE SYSTEM. I decided to see how the cylinder worked when it was attached to the fresh water and engine pipes without the outer case. It was easy to temporarily mount just the cylinder under the floorboards and connect the four hoses. I first switched the water pump on that pressurizes the whole of the boats freshwater system to about 35psi. The pump is an automatic type that shuts off when pressure is achieved, but if the pump still recycles spasmodically it indicates a leak somewhere within the system. The pump quickly filled the cylinder and reached pressure then – silence!

I decided to see how the cylinder worked when it was attached to the fresh water and engine pipes without the outer case. It was easy to temporarily mount just the cylinder under the floorboards and connect the four hoses. I first switched the water pump on that pressurizes the whole of the boats freshwater system to about 35psi. The pump is an automatic type that shuts off when pressure is achieved, but if the pump still recycles spasmodically it indicates a leak somewhere within the system. The pump quickly filled the cylinder and reached pressure then – silence!

Next I started the engine, and after it reached operating temperature I opened the valve to allow hot engine water circulate through the tank pipe and increase the temperature. I inspected for leaks and found none. This was reassuring, but it still didn't solve the leakage problem, and I began to wonder if I had dreamt it. I brought the cylinder back to my garage and reassembled the outer casing with new pop rivets, then reinstalled it into the boat.

It was only at this point that I noticed that one of the 90 degree fittings I had made to connect the fresh water pipe to the tank, had been made with a short piece of neoprene pipe. When neoprene pipes heat up they soften and the connection might have leaked, or perhaps the clamp had not been tight enough to make a watertight seal. It is also possible that the hose clamp was tight initially, but leaked as the pipe warmed up.

It was only at this point that I noticed that one of the 90 degree fittings I had made to connect the fresh water pipe to the tank, had been made with a short piece of neoprene pipe. When neoprene pipes heat up they soften and the connection might have leaked, or perhaps the clamp had not been tight enough to make a watertight seal. It is also possible that the hose clamp was tight initially, but leaked as the pipe warmed up.

All this sounded possible, but it did not explain why there had been no sign of any leak on the outside of the front panel?

The answer turned out to be “Elementary my dear Watson”; When the neoprene pipe was pushed on to the cylinder pipe it went further inside the front caseby about 1” inch. Therefore, any leak coming from this connection would then dribble down the inside of the case, not the outside, and eventually emerge out of the bottom of the tank precisely where I first saw it. I did not see any leaks when I first installed the neoprene connection, because the insulation absorbed the water leak to begin with. Where is Sherlock Holmes when you need him? Also, when making all my tests the neoprene pipe was not connected to the cylinder pipes at all, and anyway I should not have used a neoprene pipe on a connection that will become warm - that also is elementary. I quickly replaced the neoprene with the correct size rubber hose, but I left the hose outside of the tank this time. This was an Infuriating deduction that made me annoyed with myself,

It was with some trepidation that I switched the water pressure pump on. It took a few minutes for the tank to fill and it finally gushed out of the sink faucet and the pump stopped when I closed it. Now that I knew the tank was full I examined the connection: dry as a bone! There was subsequently no leaks out of the bottom of the tank either.

The moral of this story, (always in hindsight of course), is that it is always better when trying to solve oddball problems to go to the last thing that has been done, and work backwards. If I had done this I might have deduced that the leak was in the neoprene hose connection, and running down the inside of the tank case, and I could have solved the problem by simply changing the pipe.

A mysterious leak in a water tank is finally discovered, only after everything else has been dismantled and rebuilt.