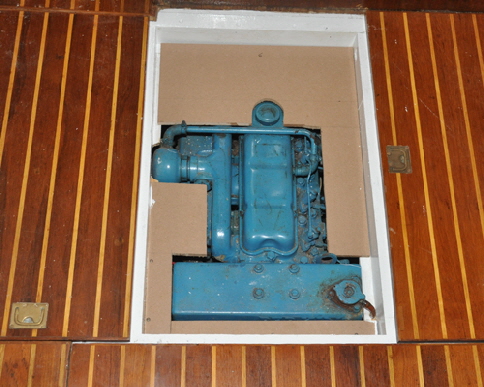

Sound deadening of the machinery under the floorboards is achieved with muliple thicknesses of dense fiberboard that has a density of 44 lbs per cubic foot and is used to make stereo speaker boxes. The sound deadening properties of this ½” inch thick board are actually better than the 3/4” inch thick marine plywood sole that is roughly 35 lbs per cubic foot.

Sound deadening of the machinery under the floorboards is achieved with muliple thicknesses of dense fiberboard that has a density of 44 lbs per cubic foot and is used to make stereo speaker boxes. The sound deadening properties of this ½” inch thick board are actually better than the 3/4” inch thick marine plywood sole that is roughly 35 lbs per cubic foot.

The floorboards have a combined thickness of 4” inches with a density of about 80 lbs per cubic foot. A layer of thermal insulation in the space between the boards reduces heat coming through into the saloon.

All the boards can easily be lifted to give access to the machinery below. This method considerably reduces engine and pump noise in the saloon.