Equipment breakdowns are inevitable on older boats, some due to age, some to neglect of the previous owner, and some my own fault. I smiled when I saw a forum members signature: If it ain't broke, it will be when I fix it. There is much truth in this, especially for the Jack-of-all-trades boat fixer-upper like me. The biggest problem I have had to fix so far, has been the 6.5 Kw Kubota generator.

It all started when I smelled shellac coming from the control box and discovered the circuit board insulation completely melted down. How it continued to work I don't know but it did, that is, until I found two unattached wires and decided they should be joined together—wrong, big mistake! When I started the generator engine it immediately started smoking and nearly chocked me, until I managed to switch it off using the manual lever.

I had shorted out the stator coils and there was no option but to buy a new generating section. I bought one wholesale from the manufacturers but it was still $2,200 (“whata mistaka to maka” - thats a British thing from “Allo Allo” a silly BBC series). I did manage to get $20 scrap for the old bits though.

I had shorted out the stator coils and there was no option but to buy a new generating section. I bought one wholesale from the manufacturers but it was still $2,200 (“whata mistaka to maka” - thats a British thing from “Allo Allo” a silly BBC series). I did manage to get $20 scrap for the old bits though.

I carefully dismantled the genny and made notes how to reinstall the new one. It actually was not a very difficult job because I didn't have to disturb the heavy engine section. It was a bit like rebuilding an electric motor, just bigger and heavier. Happily all the machinery on a Down East 45 is very accessible, directly below the saloon floorboards. When it was all put back together I started the engine and we saw 125 volts flick on to the meter, fabulous!

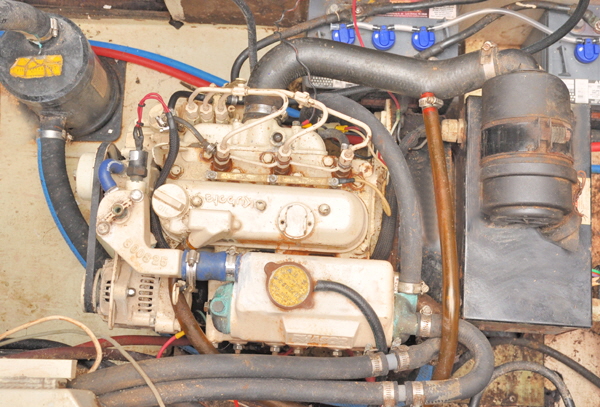

A month or two later I decided to inspect the raw water pipes on the generator engine. This had always run warm under load and some of the water pipes were only ½” inch diameter when the spec’ calls for 3/4” inches. Inspection revealed many pipes and waterways encrusted to less than half their diameter, so they needed attention anyway.

You would think changing ½” inch pipes for 3/4” inches would be simple enough? But not when you temporarily bridge the anti-siphon discharge pipes then run the engine, then leave it for weeks while you go on vacation. I didn't know any better, but without the anti-siphon sea water can filter back into the cylinders. So when I came to start the engine it would not budge one inch, until I removed the injectors and a stream of dirty black water shot out as high as the ceiling.

A compression test confirmed my worst fears: # one cylinder 85psi, # two 105psi and # three 125psi, and a small diesel like the Kubota needs about 350 psi in order to fire. Clearly, the piston rings had seized so removing the head did not initially show anything amiss. I had to inspect at least one piston, that was easier said than done, because the whole assembly weighs about 350 lbs.

I rigged a four-part tackle supported through the saloon hatch and hoisted the motor and its generator section into the upright position so I could unscrew the oil pan. The pan bottom was encrusted with about half an inch of old dry oil that had to be scraped away with a chisel. I then unbolted one connecting rod and withdrew the piston to find the rings completely rusted to the piston, I therefore decided to buy new pistons instead of just fitting new rings.

The first rebuild procedure was honing the bores that I did with a Flex Hone. This is a funny looking devise like a Dandelion stem that is reamed up and down the bore on an electric drill. After this the new pistons and rings slid easily into their clean bores and new big end bearings completed this operation, closed off by replacing a nice clean sump pan.

The first rebuild procedure was honing the bores that I did with a Flex Hone. This is a funny looking devise like a Dandelion stem that is reamed up and down the bore on an electric drill. After this the new pistons and rings slid easily into their clean bores and new big end bearings completed this operation, closed off by replacing a nice clean sump pan.

Lowering the machine was a lot easier than hoisting it, but it still took me another day to refit the cylinder head and all pipes and electrical devises. This included three new exhaust valves, and drilling out and re-tapping a new water drain cock into the block, that has completely clogged.

I was dreading the moment of starting the engine, but after carefully bleeding the fuel system I turned the switch and lo! the baby fired up after only a few seconds. I didn't know whether to kick it or kiss it? It now runs smoother, quieter and cooler and has 15 lbs more oil pressure. It clearly gives more power but, then it jolly well should do, it's had a triple bypass!

We now have what I hope is a thoroughly reliable, almost new, 6.5 Kw generator, that should serve us well. It runs both air conditioners, the water heater, an electric kettle and pumps 15 volts into the batteries, all at the same time.

Now, back to the rest of my list…