We had moved house from Orlando Florida to Fairfield Harbour, near New Bern, North Carolina, and I now needed to move Britannia from Cape Canaveral, where she had been docked for five years, up to Fairfield. Fairfield Harbour (fh-poa.com) . It was January 2022.

We had moved house from Orlando Florida to Fairfield Harbour, near New Bern, North Carolina, and I now needed to move Britannia from Cape Canaveral, where she had been docked for five years, up to Fairfield. Fairfield Harbour (fh-poa.com) . It was January 2022.

Britannia is a powerful ocean cruiser, but had not been to sea for some time. I therefore thought it prudent to have a trial run up the Intracoastal waterway, “Just to check that everything works.” I told my wife, before stepping out into the Atlantic and a voyage of 530 miles to Beaufort Inlet, NC, then up a river into the Pamlico Sound and New Bern.

My crew was Bob Snell, a very experienced mariner and his girlfriend Lisa, who was quite new to boating. An intracoastal passage would also help Lisa acclimatize to the boat, before an ocean passage of possibly three or four nights.

All our friends from five years in the marina were gathered on the dock to see us off. The lines were let go and I eased the gear shift lever astern to back out of the slip, but it was rock solid. The lines went back on, while I freed the shifter with some WD40. Not a very auspicious departure, but we finally started to motor north at a steady seven knots expecting to easily make New Smyrna Beach by nightfall a mere 47 miles.

UNUSUAL BREAKDOWNS.

We were just north of Titusville when the saloon suddenly started to fill with acrid smoke and I immediately cut the engine, thinking we were on fire, as it must have looked like to anyone on shore. I eased Britannia into the side of the channel and she came to a halt in the soft mud. We flung open all hatches from on deck and the breeze began to slowly disperse the smoke. An inspection all around the engine bay showed no sign of leaks. “Start her up for just a minute and I’ll see if we have any pressure leaks,” said Bob. Indeed, this immediately revealed a small crack in the pressure side of fuel lift pump, and fuel was being sprayed all over the hot engine block. Thank goodness diesel fuel does not self-ignite, because if it had been a gas engine there might well have been an explosion.

Bob wrapped the leak with duct tape to prevent fuel spurting all over the block, and we limped back to the Titusville mooring field where we picked up a buoy.

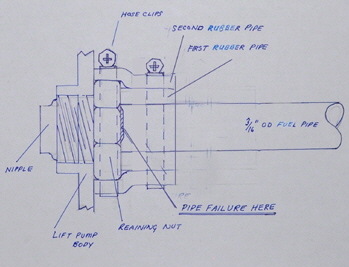

The crack in the pipe was right against the nut securing the pipe to the lift pump and it was not possible to splice it with a piece of rubber tubing. After some discussion Bob and I devised an intricate way we hoped would stop the leak, but it required rubber tubing of the size I didn't have on board.

I lowered the dinghy from its davits and the outboard was screwed to the transom, but it stubbornly refused to run continuously and would only fire with a squirt of engine starter fluid into the carburetor intake, then it died again indicating a carburetor jet blockage. It was too far to row to the marina dock, so Bob hitched a lift on a passing dinghy to try to find suitable rubber fuel pipes. I took the carburetor off the outboard and cleaned everything with carb’ cleaner that finally had it running.

Bob returned with a selection of different sized fuel pipes and I sliced a short length of rubber tubing down its length at about 65 degrees, so it could be wrapped around the pipe and pushed up against the crack near the nut. Cutting the tube at an angle instead of straight allowed the edges to overlap as they were clamped together, with a better chance of making a tight seal. I then made a similar “bandage” of a larger diameter tube that fitted over the actual nut head. The two slices were positioned at 180 degrees to each other then clamped tight with two small hose clamps, one over the nut head and one directly over the crack in the pipe. All this was very difficult to fit because the lift pump is under the exhaust manifold and impossible to see without hanging upside down over the engine. This done I gingerly pressed the engine start button and waited for Bob to pronounce the success, or otherwise of our seal. “Dry as a bone” was his exclamation. Wow!

Bob returned with a selection of different sized fuel pipes and I sliced a short length of rubber tubing down its length at about 65 degrees, so it could be wrapped around the pipe and pushed up against the crack near the nut. Cutting the tube at an angle instead of straight allowed the edges to overlap as they were clamped together, with a better chance of making a tight seal. I then made a similar “bandage” of a larger diameter tube that fitted over the actual nut head. The two slices were positioned at 180 degrees to each other then clamped tight with two small hose clamps, one over the nut head and one directly over the crack in the pipe. All this was very difficult to fit because the lift pump is under the exhaust manifold and impossible to see without hanging upside down over the engine. This done I gingerly pressed the engine start button and waited for Bob to pronounce the success, or otherwise of our seal. “Dry as a bone” was his exclamation. Wow!

With this breakdown repaired and a working outboard, I felt we were getting somewhere, after all this was the purpose of the ICW trip. The following morning we decided to continue north towards New Smyrna Beach, where we hoped to find material to be able to make a more permanent repair to the leak.

We had not gone three miles when steam started seeping up through the saloon floorboards. I immediately anchored in the fairway and stopped the engine. An inspection revealed a crack part of the way around the rim of the water filler neck, on the engine header tank. This had reduced the engine pressure to zero and boiled all the water out of the header tank. Oh! and did I mention that the engine water temperature gauge had stopped working, so we could not spot the engine temperature rise, allowing it to overheat and blow the filler cap. The gauge was working fine when we left.

We had not gone three miles when steam started seeping up through the saloon floorboards. I immediately anchored in the fairway and stopped the engine. An inspection revealed a crack part of the way around the rim of the water filler neck, on the engine header tank. This had reduced the engine pressure to zero and boiled all the water out of the header tank. Oh! and did I mention that the engine water temperature gauge had stopped working, so we could not spot the engine temperature rise, allowing it to overheat and blow the filler cap. The gauge was working fine when we left.

I had a pack of JB Weld, a two-part epoxy that is supposed to be heat-resistant up to 450 F. Bob meticulously cleaned the filler neck and applied a good thick layer of the goo all the way around the rim. Unfortunately the pack was the extended curing version, so we decided to let it set overnight before starting the engine. We were safe enough (I thought), anchored at the edge of the calm channel. At 2.30 am the wind proved me wrong and pushed us to the side of the channel, where Britannia began bumping sideways on the bottom. This became excessive as the wind picked up to 25 knots and we had no engine with which to pull her off, or which we could even rely upon to get us back to Titusville in the pitch-black night.

OUR KNIGHT WITH SHINING TWIN VOLVO'S TO THE RESCUE I called Towboat US, who I had only joined a week previously, “But I don't suppose we will need it” I told my wife.

I called Towboat US, who I had only joined a week previously, “But I don't suppose we will need it” I told my wife.

Within an hour Kevin Derr the towboat US operator from Titusville passed over the twin looped hawser bridles that we fed through Britannia’s bow fairleads and over the Sampson post bits on each side of the bowsprit. The anchor was hauled in and we were swiftly on our way back to the mooring field, where it took Kevin a few tries to steer us onto a mooring buoy in the wind and dark. It had certainly been a memorable night for Bob and I, Lisa having stayed in bed the whole time, and it would have been nice to have had a cup of tea.

One of the things that had continued to work faithfully was the 6.5-kilowatt generator that powered the air conditioning, but while the genny kept running the AC suddenly failed showing a water shortage fault, but that could wait until the morning. We all went back to bed and presumably also Kevin, our gallant rescuer.

In the grey light of dawn, with the wind still blowing strongly the AC water filter was unscrewed and I was absolutely astonished to find the whole of the 6” inch long round gauze filter completely solid with muck! It must have been drawn into the filter when we were bumping against the side of the channel. The pipework from the seacock to the AC pump was also clogged, so it all had to be removed and blown clear before the AC would work again. Anyone who has lived on a boat in Florida will know that air conditioning is very necessary, even in January.

Another annoying fault was the engine stop solenoid had begun to fail intermittently, and it was sometimes necessary to lift the floorboards to pull the lever by hand to stop the engine. It seemed like as soon as we fixed one problem another reared its head, none of which were apparent before setting out.

RETURN TO BASE.

Over breakfast I held a council of war and it was reluctantly decided we should return to Cape Canaveral to repair the faults, then think about trying again later, and in retrospect it was the correct decision.

The water filler cap repair looked like it had set hard, but after only half an hour of engine running the pressure blew through the edges of the sealant and we had to slow the motor to a tickover as we limped back to Canaveral, continuously refilling the header tank as we went. It took five hours in light airs limply assisted by the squaresail.

Poor old ‘Perky’ Perkins, (and his owner) were worn out, and I think it is a fine testament to these sturdy old engines that it ran at all considering the condition it was in. To say I was exhausted, both physically and mentally would be an understatement. I simply could not bring myself to start the repairs that needed new parts for the lift pump leak and the header tank cap, so I was quite happy to close the boat up then rent a car and drive for 10 hours, 730 miles north, to our new house in North Carolina, where it snowed.

EPILOGUE Apart from the outboard motor refusing to start, none of the other breakdowns could have been predicted. A fuel pipe break, a water filler neck crack, and a failed temperature sender are rare failures. Therefore the moral is that a boat owner needs to learn every single aspect of his boat and develop many skills, plumbing, electrics, mechanical, engine, AC, etc., in order to be able to fix the unexpected.

Apart from the outboard motor refusing to start, none of the other breakdowns could have been predicted. A fuel pipe break, a water filler neck crack, and a failed temperature sender are rare failures. Therefore the moral is that a boat owner needs to learn every single aspect of his boat and develop many skills, plumbing, electrics, mechanical, engine, AC, etc., in order to be able to fix the unexpected.

After buying all the new parts I returned to the boat with renewed energy. I bought a short length of fuel pipe that screwed into the pump where the old one had failed. This enabled me to make a good connection to the existing pipe using a short piece of rubber fuel line and the correct type of fuel line clips. These fuel line clips are better than tiny hose clamps because they exert equal pressure all the way round a rubber hose. On a very tiny regular hose clamp the worm drive is not circular so they don't clamp correctly on thin pipe. I also bought a new lift pump and while fitting it I discovered two cracks in the 9’6” inches long fuel line from the tanks to the pump, so I had to buy new fuel line as well. It took a long time to bleed the new fuel line, all the way from the tanks, through four filters and the new lift pump to the engine, but it eventually fired and has worked perfectly so far.

The engine stop solenoid turned out to be a bad earth to the engine block and has not failed since.

PARTS COSTS:

Filler cap and shoulder $195, yes $195!

Water temperature gauge sender $17

Section of new lift pump pipe $50.

I also bought a new lift pump for $50 and filter for $15. The new fuel line was $105. TOTAL $432.

Boats! Who’d av’ em?