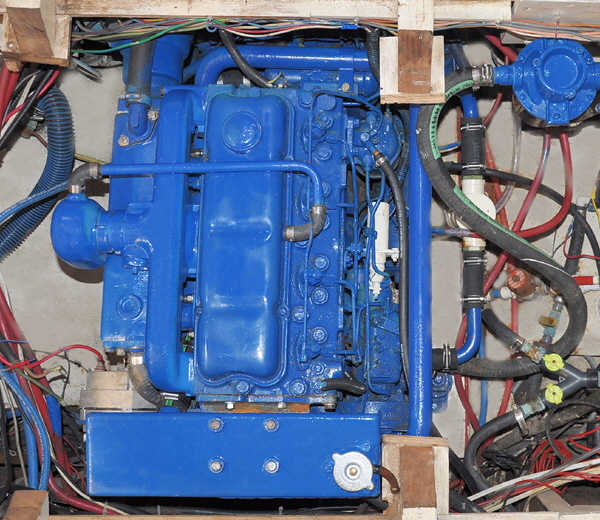

Operating a seawater cooled motor in the Intracoastal waterways in Florida results in the occasional grounding. This does not normally cause damage for a long keel boat like Britannia, because the bottom is mostly soft black mud, but depending on how hard she goes on the prop is certain to disturb lots of silt and sludge that can be drawn into an engine water cooling intake and cause havoc.

The first sign of this is often a rise in the engine's temperature along with a reduction in revolutions and performance. I had noticed all of these things during a few day-sails and decided to investigate.

The first sign of this is often a rise in the engine's temperature along with a reduction in revolutions and performance. I had noticed all of these things during a few day-sails and decided to investigate.  All the parts of the cooling system were removed to be examined and cleaned. This operation was done in 2022.

All the parts of the cooling system were removed to be examined and cleaned. This operation was done in 2022.

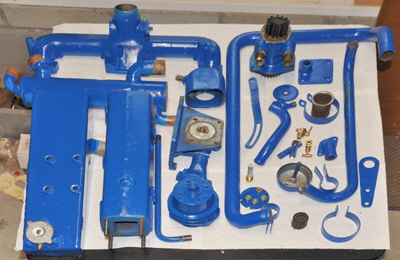

The heat exchanger with it’s honeycomb of tiny tubes inside carrying the engines fresh water to where it is cooled by the flow of seawater was clogged up and needed to be “rodded” to allow water to pass through. The oil and gearbox heat exchanger was also cleaned. New pipes were installed and new gaskets from the Perkins dealer.

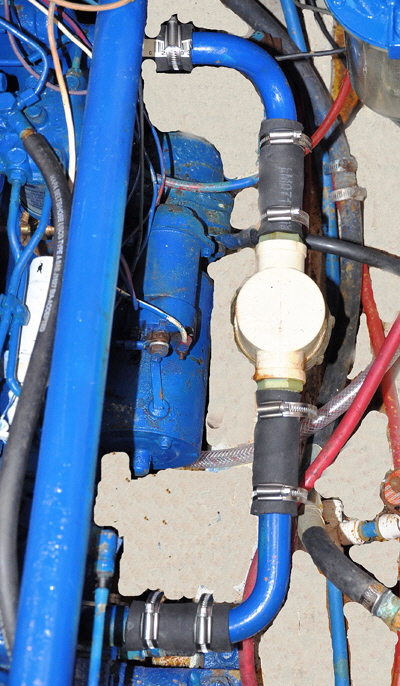

The correct type of hose clips for pressurized engine pipes are the sort that have indentations where the worm drive engages in the continuous stainless band. The clamps with open slots are thinner and weaker and liable to fail over time. Twenty one of these weaker clips were

The correct type of hose clips for pressurized engine pipes are the sort that have indentations where the worm drive engages in the continuous stainless band. The clamps with open slots are thinner and weaker and liable to fail over time. Twenty one of these weaker clips were  replaced.

replaced.

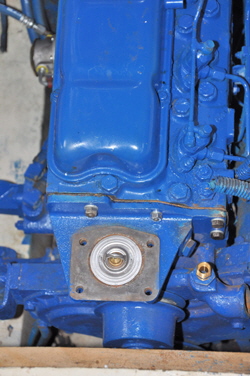

The engine block freshwater drain taps were dismantled and cleaned, then the holes in the block reamed out with a drill bit releasing a torrent of filthy brown water.

After cleaning everything with degreasing fluid the parts were spray painted ready for re-assembly.

After cleaning everything with degreasing fluid the parts were spray painted ready for re-assembly.

A second water filterwas installed directly after the impeller pump to catch anything that managed to pass through the water pump.

The engine oil drain tap was replaced with a 90 degree elbow and a reinforced pipe up to a hand vacuum pump, making changing the oil much easier.

After rebuilding the engine was started and wwithin seconds an absolute torrent of water gushed from the exhaust pipe. The temperature slowly rose to 180F then stopped as the new thermostat opened, allowing for full circulation of water throughout the engine. On a speed test the temperature remained steady at 2,000 rpm.