Rope is used to turn nearly all furling drums and some, like code-zero sail furlers and the old Hood in-mast system employ a continuous line. The French made Facnor furling drivers on the mainsail and squaresail of Britannia are operated in this way and have long lines that pass once around the driver drum then out the other side and back to the cockpit. The driver jaws grip the line much like on a self-tailing winch and this in turn winds the sails in and out . Using a single line therefore results in a very long tail on one end or the other whether the sails are furled or unfurled,

Rope is used to turn nearly all furling drums and some, like code-zero sail furlers and the old Hood in-mast system employ a continuous line. The French made Facnor furling drivers on the mainsail and squaresail of Britannia are operated in this way and have long lines that pass once around the driver drum then out the other side and back to the cockpit. The driver jaws grip the line much like on a self-tailing winch and this in turn winds the sails in and out . Using a single line therefore results in a very long tail on one end or the other whether the sails are furled or unfurled,

The mainsail on Britannia needs sixteen rotations of the driver and the squaresail needs nineteen. The

The mainsail on Britannia needs sixteen rotations of the driver and the squaresail needs nineteen. The  squaresail rope tail is 45” feet long and the main 35” feet. These lines all lead back to the cockpit and along with two furling head sails and a between mast staysail furler the rope decks can become very cluttered. If these long lines could be made into continuous loops they could be just wound round the winch and return without having yards of rope to coil every time they are operated.

squaresail rope tail is 45” feet long and the main 35” feet. These lines all lead back to the cockpit and along with two furling head sails and a between mast staysail furler the rope decks can become very cluttered. If these long lines could be made into continuous loops they could be just wound round the winch and return without having yards of rope to coil every time they are operated.

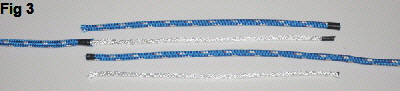

Rope makers describe different methods to make a continuous loop with double braided line in their manuals and web videos. But they all result in a splice that is thicker than the rest of the rope and will not pass around the jaws of drum drivers or through clutches and blocks that can cause the possibilities of serious jams. Ideally, any continuous splice needs to be no thicker than the rest of the rope and needless to say, the splice also has to be very strong. After a lot of experimentation and testing I finally arrived at a method to splice two ends of a double braided line, that results in a uniform thickness throughout.

Cautionary note: Remember that before making a continuous loop rope it must first be rove through any closed sheaves, pulleys, or clutches, because it can't be threaded through afterwards since it will have no ends.

TOOLS.

A special fid, called a Splicing Wand makes the process of forming a continuous splice very easy. It was invented by the late Brion Toss, the renowned rigger from Port Townsend, Seattle. It consists of a 14 ”inch long thin hollow stainless steel tube with a handle on one end and a smooth slotted opening on the other. A strong thin line passes through the tube and comes out as a loop on the other end to grip a splice tail that is then held securely with the locking knob on the handle. The tail can then be pulled through the cover, which is the opposite of using a normal fid that must be pushed through with a pusher rod. The wand is also a great improvement on a thin wire line puller. The only other tools needed are a sharp knife and a method to heat-seal the rope ends. Both a heat gun and a gas lighter can be used for this operation.

A special fid, called a Splicing Wand makes the process of forming a continuous splice very easy. It was invented by the late Brion Toss, the renowned rigger from Port Townsend, Seattle. It consists of a 14 ”inch long thin hollow stainless steel tube with a handle on one end and a smooth slotted opening on the other. A strong thin line passes through the tube and comes out as a loop on the other end to grip a splice tail that is then held securely with the locking knob on the handle. The tail can then be pulled through the cover, which is the opposite of using a normal fid that must be pushed through with a pusher rod. The wand is also a great improvement on a thin wire line puller. The only other tools needed are a sharp knife and a method to heat-seal the rope ends. Both a heat gun and a gas lighter can be used for this operation.

METHODOLOGY.

Simply put, the splice is formed by interlacing the cover and core inside each other in opposite directions.

Overlap the two rope ends for the length of the splicing wand, i.e. 14” inches. Loosely tape both ends of the covers to stop them fraying. Slide a 1 1/2” inch length of heat shrink tube down one rope. Note: Use marine-grade heat shrink with adhesive in the tube that melts and strengthens the splice and makes the joint waterproof.

Overlap the two rope ends for the length of the splicing wand, i.e. 14” inches. Loosely tape both ends of the covers to stop them fraying. Slide a 1 1/2” inch length of heat shrink tube down one rope. Note: Use marine-grade heat shrink with adhesive in the tube that melts and strengthens the splice and makes the joint waterproof.

Milk the outer cover back from the core for 14” inches, then cut off the core and heat seal the end to stop it from fraying. Note: This should be done carefully with a gas lighter to only melt the end of the core and not make it larger.

On the other rope, extract the core completely out of the cover at the 14” inch point then cut the cover off completely at that point, loosely taping the end to stop it fraying. Do not heat seal the end of the core yet, because that will make it more difficult to pull through the other cover. Note: You will now have a rope with no core and another with no cover, each 14” inches long.

On the other rope, extract the core completely out of the cover at the 14” inch point then cut the cover off completely at that point, loosely taping the end to stop it fraying. Do not heat seal the end of the core yet, because that will make it more difficult to pull through the other cover. Note: You will now have a rope with no core and another with no cover, each 14” inches long.

Carefully wiggle the wand into the empty cover at 14” inches making sure it enters cleanly between the weaves, then milk it along the cover until it comes out the end. Attach the end of the other core to the wand and pull it through the empty cover until it comes out with the wand. The wand can now be unhooked from the core. Heat seal the end of the exposed core and milk it back into the cover.

Carefully wiggle the wand into the empty cover at 14” inches making sure it enters cleanly between the weaves, then milk it along the cover until it comes out the end. Attach the end of the other core to the wand and pull it through the empty cover until it comes out with the wand. The wand can now be unhooked from the core. Heat seal the end of the exposed core and milk it back into the cover. Milk both ends of the outer covers along the core until they meet each other then wrap a piece of tape tightly around the joints to keep them together and stop them fraying. Work the rope back and forth until it is an even thickness throughout.

Milk both ends of the outer covers along the core until they meet each other then wrap a piece of tape tightly around the joints to keep them together and stop them fraying. Work the rope back and forth until it is an even thickness throughout. Withdraw two single strands out of the cover you just cut off, (there are usually three strands in each weave), and thread them on a sharp sail needle to do the lock stitching. Using strands from the same rope produces an invisible stitch and a much neater and stronger splice than whipping twine. Starting about 1 1/2” inches from one side of the cover joint lock stitch the covers together over the tape, with tight stitches, in and out at about 1/4” inch spacings for 1 1/2” inches on the other side of the joint. As you pull the thread tight it will tend to squash the rope, so stitch back at 90 degrees that will normalize the rope. Tie the four loose ends together then bury them back inside the cover. Note: The purpose of this it to lock-stitch the cover and the core to each other.

Withdraw two single strands out of the cover you just cut off, (there are usually three strands in each weave), and thread them on a sharp sail needle to do the lock stitching. Using strands from the same rope produces an invisible stitch and a much neater and stronger splice than whipping twine. Starting about 1 1/2” inches from one side of the cover joint lock stitch the covers together over the tape, with tight stitches, in and out at about 1/4” inch spacings for 1 1/2” inches on the other side of the joint. As you pull the thread tight it will tend to squash the rope, so stitch back at 90 degrees that will normalize the rope. Tie the four loose ends together then bury them back inside the cover. Note: The purpose of this it to lock-stitch the cover and the core to each other.

![]() Smooth the cover back to where the two inner cores meet, you will feel where they meet because of the solid heat seals. Now lock stitch this core joint the same as the previous stitch. Make a few back and forth stitches on either side of the heat seals to pull them together. Note: This stitching locks the cover to the core joint. Slide the heat shrink tube that was fitted at the beginning of this operation over the cover joint on top of the tape and stitching, then shrink it to cover the joint. Note: It is best to use a heat gun for this operation, but if using a live flame be careful not to damage the outer cover of the rope. Now lock stitch the center of the splice for one inch both ways that helps to distribute the load on the splice ends.

Smooth the cover back to where the two inner cores meet, you will feel where they meet because of the solid heat seals. Now lock stitch this core joint the same as the previous stitch. Make a few back and forth stitches on either side of the heat seals to pull them together. Note: This stitching locks the cover to the core joint. Slide the heat shrink tube that was fitted at the beginning of this operation over the cover joint on top of the tape and stitching, then shrink it to cover the joint. Note: It is best to use a heat gun for this operation, but if using a live flame be careful not to damage the outer cover of the rope. Now lock stitch the center of the splice for one inch both ways that helps to distribute the load on the splice ends.

STRENGTH.

As with any rope splice it would be reassuring to know its strength, relative to the tensile strength of the original rope. Tensile strength is the load on which a new rope can be expected to break when tested on approved ASTM, (American Society for Testing Materials), rope testing equipment. The 3/8 ”inch double braided polyethylene line I used is supposed to have a tensile strength of between 3,000 and 4460 lbs depending on which manufacturers tables you

As with any rope splice it would be reassuring to know its strength, relative to the tensile strength of the original rope. Tensile strength is the load on which a new rope can be expected to break when tested on approved ASTM, (American Society for Testing Materials), rope testing equipment. The 3/8 ”inch double braided polyethylene line I used is supposed to have a tensile strength of between 3,000 and 4460 lbs depending on which manufacturers tables you  read.

read.

I had one of my continuous splices tested by Miami Cordage, a Florida commercial rope maker who supplies the US Navy and makes all types of rope. www.miamicordage.com. They have a massive 40’ foot long hydraulic testing rig that can stretch any rope to destruction, including the massive hawsers used to moor aircraft carriers. My puny ten foot long piece of string with the splice in the middle was stretched until the splice eventually broke at 2031 lbs. This is far more than the torque required to rotate the drivers on my two sails, even when they are pulling hard and both splices have performed flawlessly thus far. The loop has greatly simplified the operation of furling the mainsail and squaresail and I now have a much neater cockpit.

Warning: It is inadvisable to use any type of spliced rope for personal safety attachments like a bosun's chair or safety harness. This is because any buried splice, such as the class one eye splice, cannot be inspected. It is far better to tie these types of lines using an appropriate knot.