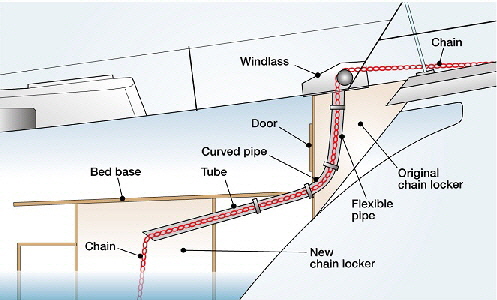

250 feet of 3/8” chain self-stows large space under the forward bunk. This has an additional advantage: 250’ feet of 3/8” inch chain weighs about 420 lbs., therefore, the further aft the chain is stowed the lighter the bow would become.

250 feet of 3/8” chain self-stows large space under the forward bunk. This has an additional advantage: 250’ feet of 3/8” inch chain weighs about 420 lbs., therefore, the further aft the chain is stowed the lighter the bow would become.

Water coming in on the chain also passes into the deep locker, and drains through two 1” inch holes in the bottom, and into the bilge, where the automatic pump sends it back where it came from.

The rear of the chain compartment formes the back of a seat between the V births and a large aperture in this pane, that gives easy access to the chain compartment without having to disturb the bunks.

|