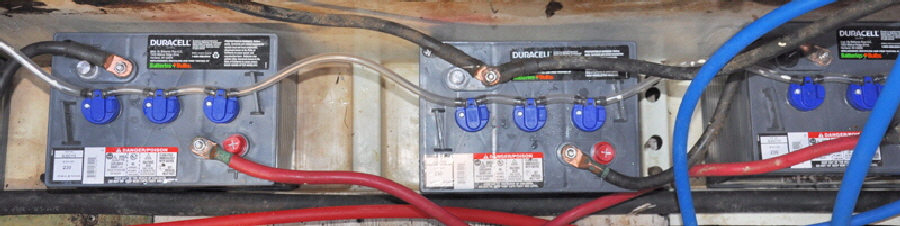

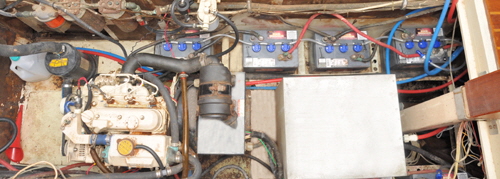

Britannia has eight golf-cart deep cycle lead-acid batteries in the house bank mounted low down in the bilge under the saloon floorboards, in two rows on either side of the 6.5 Kw diesel generator, a large water heater and the usual conglomeration of pipes, pumps and filters. The boat also has two 12-volt batteries, one in the bow for the windlass and the other as a dedicated engine and generator start. That Is a total of 36 cells to check and fill with distilled water from time to time. The process usually took over an hour because the battery caps were not easy to reach deep down in the bilge. It is of course best that heavy batteries be mounted as low as possible, and Britannia’s batteries weigh over 500 lbs I found a company appropriately called Water My Battery, www.watermybattery.com with a water filling systems for golf carts, RVs and boats.

Britannia has eight golf-cart deep cycle lead-acid batteries in the house bank mounted low down in the bilge under the saloon floorboards, in two rows on either side of the 6.5 Kw diesel generator, a large water heater and the usual conglomeration of pipes, pumps and filters. The boat also has two 12-volt batteries, one in the bow for the windlass and the other as a dedicated engine and generator start. That Is a total of 36 cells to check and fill with distilled water from time to time. The process usually took over an hour because the battery caps were not easy to reach deep down in the bilge. It is of course best that heavy batteries be mounted as low as possible, and Britannia’s batteries weigh over 500 lbs I found a company appropriately called Water My Battery, www.watermybattery.com with a water filling systems for golf carts, RVs and boats.

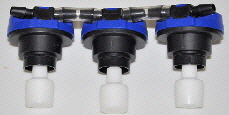

The battery caps are replaced with special valves interconnected with plastic piping. The valves open when the water level drops allowing new water to be pumped into the cell, then they close when the required level is reached. The valves are all interconnected to a common feed pipe, and the company website offers a lot of ways to find the best combination of valves and pipework,

The battery caps are replaced with special valves interconnected with plastic piping. The valves open when the water level drops allowing new water to be pumped into the cell, then they close when the required level is reached. The valves are all interconnected to a common feed pipe, and the company website offers a lot of ways to find the best combination of valves and pipework,

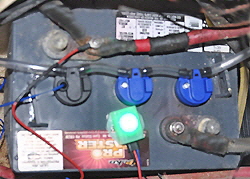

A special valve, connected to a neon light blinks green when the level is satisfactory and changes to red when the battery needs filling. The battery voltage meter on the power distribution panel showsthe voltage of each battery bank that gives me a rough idea of the condition of the charge.

A special valve, connected to a neon light blinks green when the level is satisfactory and changes to red when the battery needs filling. The battery voltage meter on the power distribution panel showsthe voltage of each battery bank that gives me a rough idea of the condition of the charge.

When the bulb was squeezed a few times it pumpes water along the tubes and into the valves and as the bulb becames harder, it indicates that all the cells have been filled and the valves had closed. The quick connect was then disconnected and the end of the pipe automatically capped off. It's that simple.

WITHOUT EVEN TOUCHING THEM